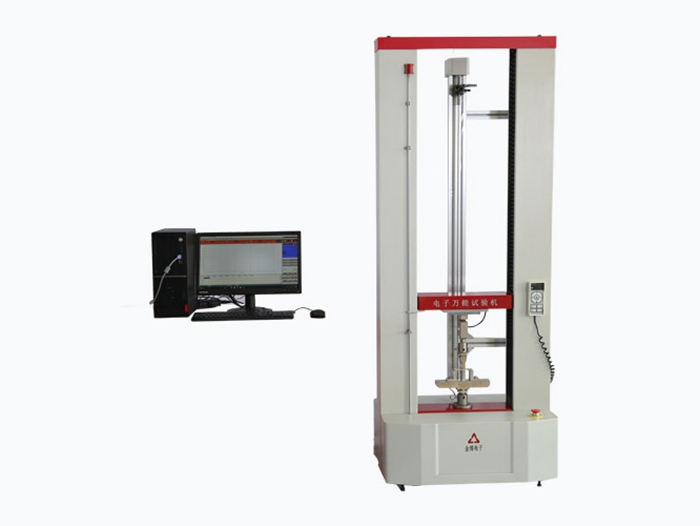

XWW-20A electronic universal testing machine

Electronic universal testing machine for all kinds of thermosetting, thermoplastic plastics, Plastic pipe tensile elastic modulus, bending elastic modulus, compression modulus, yield strength, tensile strength, breaking strength, elongation at break, compressive stress, compressive strain, shear, peel, stay, tear, penetration and other mechanical properties of the determination, suitable for engineering plastics, reinforced nylon, modified plastics, plastics, profiles, plastic pipes, plastic sheets and films and other industries of the material Material analysis and inspection.

The transmission part of the electronic universal testing machine adopts a full set of digital AC servo system, high stiffness frame structure, and adopts the method of piecewise linear correction to ensure the high precision and high stability of the force value detection part, and can choose the biaxial large deformation extensometer and small deformation extensometer; Measure the amount of deformation within the marking distance of the specimen. The host frame has its own unique shock absorption function, no need to install foundation. The universal testing machine has beautiful appearance, high precision, low noise, easy operation, accuracy can reach 1 level, and provides a variety of fixtures for users to choose.

1, ultra-rigid structure

Gantry type ultra-high stiffness frame structure, wide speed control range, sealed vertical shaft bracket, super rigidity, no clearance ball bearings, high precision, good stability.

- Three kinds of speed closed-loop control

The test can be programmed according to the above control mode, and the control mode can be switched seamlessly; The best closed-loop AC servo maintenance-free control system, high precision, high reliability; Imported reducer and ball screw improve the control accuracy and stability.

3, intelligent digital measurement and control technology

The high quality load sensor is adopted, and the piecewise linear correction method is adopted in the collection part to ensure the high precision and high stability of the load detection part. The sensor adopts the original intelligent and digital design, which gets rid of the traditional acquisition and transmission mode, and greatly improves the sampling accuracy and stability of the sensor; The sensor recognition technology can automatically identify the installation status of the sensor, the nature of the sensor, and the sensor coefficient; The change of the sensor does not need to set software;

4, high-speed processor

The high-speed processor with built-in DSP not only greatly improves the sampling rate of the system, but also improves the control accuracy and response time of the system.

5, strain measurement system

Equipped with large deformation extensiometer, good two-way follow-up, strong following, can best measure the deformation of the sample within the marking distance, so as to obtain more accurate yield strain, fracture strain and X% stress data;

6, modular design

The design concept of testing standard as the basic module of the test, the rich software test module, basically contains all the current test methods, and can add new standard modules according to user needs, with the expansion of the use of functions, to adapt to the special needs of more non-standard customers.

7, powerful software functions

The practical zero return function can reasonably and effectively eliminate the initial stress of the sample by adjusting the position of the beam, so as to obtain more perfect test results. With Chinese, English, French, German and other multi-language support, to achieve software internationalization; Provide stress-strain, load-displacement, strain-time, displacement-time and other curves, coordinate system configuration and many other functions; Embedded data analysis and comparison software, test data, test report exported to Excel. Provide auxiliary analysis means for user product research and development;

The use of network technology to achieve diagnosis and upgrade, can be free online update and upgrade at any time through the network.

- Meet the standards

|

Standard number |

Standard name |

|

GB/T 16491-2008 |

Electronic universal testing machine |

|

GB/T 1040-2006 |

Test methods for tensile properties of plastics |

|

GB/T 1041-2008 |

Test method for compression properties of plastics |

|

GB/T 9341-2008 |

Test methods for bending properties of plastics |

|

IS0 527-1993 |

Determination of tensile properties of plastics |

|

GB/T18997.1-2003 |

Stripping test of aluminum-plastic composite pressure tube |

|

GB/T 2791-1995 |

Peel strength test Method of peel test |

|

GB/T 328.8-2007 |

Tensile properties of asphalt waterproofing coils |

|

GB/T 15788-2005 |

Wide strip tensile test |

|

GB/T 13022-91 |

Test method for tensile properties of plastic films |

|

GB/T 19806-2005 |

Plastic pipes and fittings -- extrusion stripping test for polyethylene electromelt components |

|

ISO 604-2002 |

Plastics - Determination of compressive properties |

|

ISO 178-2004 |

Plastics -- Determination of flexural properties |

|

ISO 1209-1-2007 |

Rigid cellular plastics - Determination of flexural properties - Part 1: Basic bending test |

|

ISO 1209-2-2007 |

Rigid cellular plastics - Determination of flexural properties - Part 2: Determination of flexural strength and apparent flexural modulus of elasticity |

|

ASTM D 638-2008 |

Standard Test Method for Tensile Properties of Plastics |

- Instrument parameters

|

Model number |

XWW Series |

|

|

|

Test Force |

20kN |

|

accuracy level |

Grade 0.5 |

|

|

Test force indicator relative error |

Plus or minus 1% |

|

|

Deformation measurement range |

0.4 ~ 100% FS |

|

|

Relative error of deformation indication value |

Within ±0.5% |

|

|

Large deformation measurement range |

5 to 800mm |

|

|

Large deformation indication relative error |

Plus or minus 0.5% |

|

|

Relative error of beam displacement indication |

Plus or minus 0.50% |

|

|

Displacement resolution |

The 0.001 mm |

|

|

Beam speed adjustment range |

0.001 ~ 500mm/min |

|

10, instrument configuration:

|

Configuration |

Effective test width |

420mm |

|

Stretch stroke |

800mm |

|

|

Compressed space |

1000mm |

|

|

Electrical source |

220VAC-15% ~ 220VAC+10% 50Hz 1kVA |

|

|

Host dimensions |

750mm×480mm×2000mm |

|

|

Engine weight |

About 300kg |

|

|

Standard configuration |

One 20kN sensor |

|

|

1 Lenovo computer and HP printer |

||

|

1 data cable |

||

|

One manual box |

||

|

A server |

Dongling |

|

|

Sensors |

Wide gauge |

|

|

Speed reducer |

Newdart reducer |

|

|

Ball screw |

Taiwan ball screw 32mm |

|

|

Extensometer |

Import encoder |

Japanese Omron |

Note:

- This machine conforms to GB/T 16491-2008 "Electronic universal testing machine" standard requirements;

- Additional force value sensor can be selected to expand the measuring range

- The force control rate and deformation rate are related to the material of the sample, and its range can not exceed the displacement rate adjustment range;

- In order to avoid the deformation of the force sensor, the test force should not exceed 50% of the full scale of the sensor when conducting a long-term holding test;

The effective space is the test space after the installation of the stretching fixture. If the fixture is different, the stretching space data will be different.

冀公網(wǎng)安備 13080502000095號

冀公網(wǎng)安備 13080502000095號