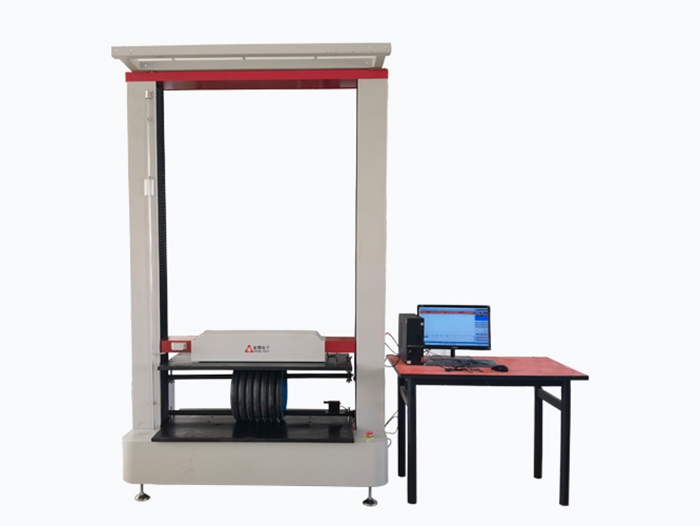

WDE series ring stiffness testing machine

First, overview

It is suitable for the determination of ring stiffness of thermoplastic pipe with annular cross section. It is also suitable for flat test, ring flexibility test and weld tensile test. It meets the requirements of PE double-wall bellows, winding pipes and various plastic pipe testing standards, and is the ideal testing instrument for scientific research institutes, quality testing departments and pipe manufacturers. PC control software, to achieve the test force, test force peak, cross beam displacement, test deformation and test curve screen display, the operation is intuitive and simple. It has the function of overload, overcurrent and overvoltage protection, and is equipped with pipe inner diameter measuring system, which can accurately measure the change of pipe inner diameter. The transmission system controls the digital AC servo motor through the distributed control system composed of PC and single chip microcomputer, drives the middle beam up and down according to the speed required by the test standard, exerts pressure on the tube sample through the sample press plate, and the force value detection part adopts the piecework linear correction method to ensure the high precision and high stability of the machine.

Second, the working principle

According to the "determination of ring stiffness of thermoplastic pipe" standard: Use the measured force value and deformation of the pipe at constant speed deformation to determine the ring stiffness. The pipe sample is placed horizontally, the compression speed of the plate is determined according to the diameter of the pipe, and the pressure is applied to the sample in the vertical direction with two parallel plates. The reaction force is generated during deformation, and the ring stiffness is calculated by the force when the section diameter direction of the tube sample is deformed to 0.03di (di is the inner diameter of the tube sample).

Third, meet the standard

In line with GB/T9647, ISO9969, ASTM D2122 and other standard requirements.

Fourth, working conditions

1, ambient temperature: 10℃ ~ 40℃ range;

2, the relative humidity of the environment within 30%-80%;

3, around no vibration, non-corrosive media environment;

4, correctly installed and adjusted to the level on a solid basis;

5, work without strong magnetic field interference, the surrounding air without strong convection.

Fifth, technical parameters

|

WDE ring stiffness testing machine |

|

|

Test force |

50kN |

|

Test force accuracy |

±1% of the indicated value |

|

Test the force measurement range |

0-50kN |

|

Test force indication error |

Within ±1.0% of the indication value |

|

Test force resolution |

5/10000 of the test force |

|

Relative error of displacement |

±1% of the indicated value |

|

Beam displacement measurement resolution |

0.001 |

|

Beam speed range |

0.1 mm/min - 500 - mm/min |

|

Efficient compression of space |

The contract shall prevail |

|

Ring stiffness test width |

1000mm |

|

Power supply |

220V±10%, 50Hz |

|

Mechanical construction |

Gate-type |

|

Overall dimensions |

The specific size shall be subject to the contract |

|

Lead screw |

Ball screw |

Sixth, configuration

|

Name |

place of origin |

Quantity |

|

Ring stiffness jig |

Jimbo |

1 set |

|

Tube inner diameter measuring system |

Jimbo |

1 set |

|

Servo speed control system |

Delta |

1 set |

|

Low noise speed reducer |

Shanghai |

1 |

|

Ball screw |

Domestic |

2 sticks |

|

Microcomputer and printer |

Domestic |

Each 1 |

|

Measurement and control software |

Jimbo |

1 set |

冀公網(wǎng)安備 13080502000095號

冀公網(wǎng)安備 13080502000095號