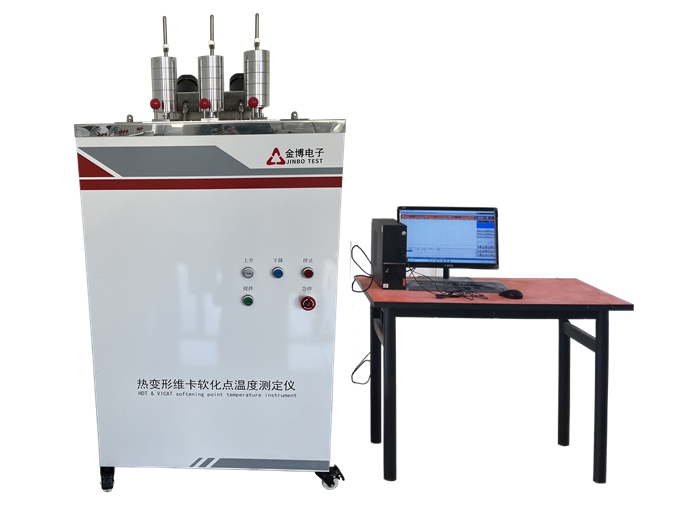

XRW-300C-3 Thermal deformation, Vica softening point temperature tester C

Overview

Mainly used for plastic, hard rubber, nylon, electrical insulation materials, long fiber reinforced composite materials, high strength thermosetting laminated materials and other non-metallic materials such as thermal deformation temperature and Vica softening point temperature determination. Easy to operate, accurate control, is a highly intelligent test instrument, widely used in colleges and universities, scientific research institutions and product quality supervision and inspection units.

The machine with Windows 98, Windows2000 or Windows7 Chinese operation interface, real-time monitoring test temperature, real-time drawing temperature and deformation curve, print test report, to achieve historical storage, mouse click deformation and temperature curve at any place, the interface will automatically display the deformation and temperature value. With the testing machine automatic lifting system, the selection of high-precision displacement sensor to measure deformation.

the working principle

VST meter: Put the sample in the liquid medium or heating box, and measure the temperature of 1mm when the standard press needle is pressed into the sample cut from the pipe or pipe fitting under the action of (50+1) N force under the condition of constant temperature rise.

Thermal deformation (HDT) definition: the standard sample is placed flat (preferably) or side-standing way to bear a three-point bending constant load, so that it produces one of the bending stresses specified in the relevant part of GB/T 1634, under the condition of constant temperature rise, the temperature when the standard deflection corresponding to the specified bending strain increment is measured.

Side standing: divided into "flat" and "side standing" two, and clearly pointed out that the preferred flat way, the side standing way is only an alternative, and will be revoked.

Span: the distance between the two contact lines between the support and the sample is changed from one (100mm) to two 64mm(flat) and 100mm (side standing), and the tolerance requirements are specified that the span L should be (100+1) mm, and the span L is (64+1) mm.

Note: Can be arbitrarily span according to user requirements.

Three methods of load deformation temperature

Method A: 1.80Mpa bending stress

Method B: 0.45MPa bending stress

Method C: 8.00MPa bending stress

Calculation of applied force:

In the three-point loading method used in GB/T 1634, the force F applied to the sample, in N, as a function of the bending stressf δ, is calculated by formula 1 or 2:

If the sample is placed preferentially (flat)

Formula 1 2δf • b •h

F=

3L

If the specimen is placed in an alternative (side-standing) manner:

Formula 2 2δf • h •b

F=

3L

In formula:

F - load in Newtons (N)

δf -- bending stress on the surface of the specimen in MPa

b -- specimen width, in millimeters (mm)

h -- specimen thickness, in millimeters (mm)

L -- The distance (span) between the specimen and the contact line of the support, in mm (mm)

Schedule 1 - Standard deflections corresponding to different sample heights

Lay the 80 mm x 10 mm x 4 mm sample for the test flat

|

Sample height (sample thickness h) /mm |

Standard deflection /mm |

|

3.8 3.9 4.0 4.1 4.2 |

0.36 0.35 0.34 0.33 0.32 |

|

Note 1: The table gives the standard deflection used in flat tests for specimens of preferred size Note 2: The thickness shown in Table 1 reflects the allowable range of variation in sample size. |

|

Table 2 corresponds to standard deflections for different sample heights

120mm x (3.0-4.2)mm x (9.8-15.0)mm for the side stand test

|

Sample height (sample thickness h) /mm |

Standard deflection /mm |

|

9.8-9.9 10.0-10.3 10.4-10.6 10.7-10.9 11.0-11.4 11.5-11.9 12.0-12.3 12.4-12.7 12.8-13.2 13.3-13.7 13.8-14.1 14.2-14.6 14.7-15.0 |

0.33 0.32 0.31 0.30 0.29 0.28 0.27 0.26 0.25 0.24 0.23 0.22 0.21 |

Meet the standard

|

Standard No. |

Standard name |

|

|

GB/T 1633 |

Thermoplastics Vica softening temperature (VST) determination |

|

|

GB/T 1634 |

Plastics - Determination of load deformation temperature |

|

|

GB/T 8802 |

Thermoplastic pipes and fittings -- determination of Vica softening temperature |

|

|

ISO 2507-1 |

Thermoplastics Pipes and Fittings - Vicat Softening Temperature |

|

|

ISO 2507-2 |

||

|

ISO 75 |

Plastics —Determination of temperature of deflection under load |

|

|

ISO 306 |

Plastics -- Thermoplastic materials -- Determination of Vicat softening temperature |

|

|

ASTM D 1525-00 |

Standard Test Method for Vicat Softening Temperature of Plastics |

|

|

ASTM D 648 |

Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position |

|

Technical parameters

|

XRW-300C-3 thermal deformation, Vica softening point temperature tester |

|

|

Temperature control range |

Room temperature ~ 300℃ |

|

Heating rate |

120℃/h (thermal deformation test), 50℃/h (Vica test) |

|

Maximum temperature error |

Plus or minus 0.5 ℃ |

|

Temperature measuring point |

1 |

|

Number of specimen racks |

3 |

|

Deformation measuring tools |

Displacement sensor |

|

Deformation measuring range |

0 to 10mm |

|

Deformation measurement error |

+ / - 0.005 mm |

|

Sample support span |

64mm(flat preferred), 100mm (side stand) |

|

Heating medium |

Methyl silicone oil or transformer oil |

|

Cooling method |

Natural cooling above 150℃, water cooling or natural cooling below 150℃ |

|

Temperature protection |

Dual temperature control upper limit protection |

|

Control mode |

MCU and PC distributed control system |

|

Sample extraction method |

Sample stand automatic lifting system |

|

Instrument Dimensions |

640X400X1300mm |

|

Power source |

2500VA 220VAC 50HZ |

Configuration

|

Name |

Quantity |

|

Host |

One |

|

Sample holder |

Three |

|

Hot deformation indenter |

Three |

|

Vica press needle |

Three |

|

Electric box |

One (attached to the main engine) |

|

Displacement sensor |

Three branches |

|

Temperature sensor |

One |

|

Power cord |

One |

|

Weights |

A set |

|

Signal wire |

One (attached to the main engine) |

|

Brand name computer |

One |

|

A color inkjet printer |

One |

|

A Chinese version of the operating system under the test software |

1 set (lifetime maintenance) |

冀公網安備 13080502000095號

冀公網安備 13080502000095號